Case studies

Graymont’s new Kiln 2 dust extractor plays a key role in its environmental care policy

Sustainability and environmental care are a key focus of Graymont, and DUSTEX was briefed to design a dust extractor that reduces air emissions, improves energy efficiency, and reduces waste.

Read MoreJackson Industries’ labour saving dust collector with explosion protection

A new pulse jet dust collector with explosion protection was custom-made by DUSTEX to fit alongside Jackson Industries’ existing cyclone. The improved dust extraction system has significantly freed up labour and space, as well as creating a better working environment.

Read MoreGolden Bay Cement’s cost-effective upgrade with a bin vent filter and integral fan

DUSTEX worked with the in-house team at Golden Bay Cement on a partial upgrade of a dust collector. The cost-effective solution was to supply a bin vent filter with an integral fan that mounted directly on top of the waste handling system.

Read MoreNu-Age Plaster save money with a second hand dust collector customised with new ducting and dust extraction hoods

Nu-Age Plaster wanted to improve working conditions in their manufacturing plant, but cost was an issue. DUSTEX found an ideal second-hand dust collector, and manufactured new ducting and dust extraction hoods to suit.

Read MoreChemical Feed Solutions enjoy easier waste disposal due to bag dumps with integral dust collectors

DUSTEX designed and supplied 25kg bag dumps with integral dust collectors to Chemical Feed Solutions. This combined system avoids problems associated with the collection and disposal of waste material.

Read MoreWinstone Wallboards’ bin vent dust collector increased efficiency and reduced maintenance time

Manufacturing GIB® plasterboard means that there’s a lot of plaster dust in the air. Winstone Wallboards needed to replace an unreliable and inefficient dust collector, and the new bin vent dust collector designed and manufactured by DUSTEX also reduced maintenance time by 20%.

Read MoreThe Cosmetic Company improved working conditions with its new dust extraction system

Working conditions in The Cosmetic Company’s blending room were very dusty and unpleasant. DUSTEX designed, manufactured and installed a dust extraction system that captured airborne dust at the source of its generation.

Read MoreOmya New Zealand upgrade to a higher capacity silo vent pulse jet dust collector

Omya New Zealand needed to upgrade their dust control system due to an increase in production. DUSTEX installed a new silo vent pulse jet dust collector that had a higher capacity, and was also easier and safer to service.

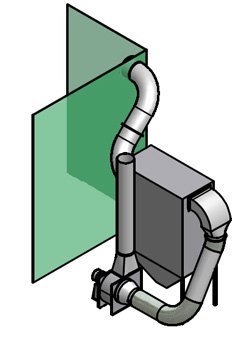

Read MoreTaylor’s Lime needed a retrofit to a decades-old dust collector

A mechanical shaker dust collector that had been in service for many decades needed an upgrade. DUSTEX’s solution to the retrofit included installing a new pulse jet dust collector top section into the existing hopper vessel.

Read MorePerry Metal Protection’s fume extraction system that meets resource consent

A new high capacity, hot dip galvanising plant needed a fume extraction system that met strict emission controls. DUSTEX’s solution consisted of a dust extraction system with a 22m high self-supporting stack.

Read More